Subframes

VELOTAK

A quick-release device that allows this operation to be carried out in a single lowering stage of the tractor. There is no need to insert pins or use special tools, as the simple movement of a lever (located on the outer side of the bearing boxes) performs the hitching and unhitching operation from the tractor. These two operations only take a few seconds.

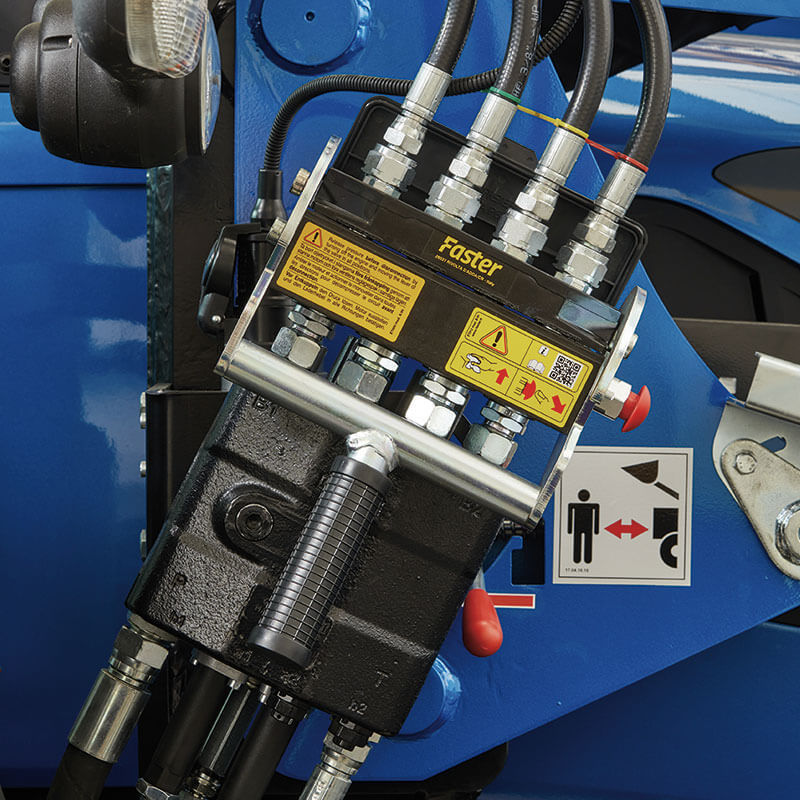

FLASH SYSTEM

The multiple connection device of the “FLASH” quick-couplings allows the connection and disconnection of all hydraulic pipes in a single movement, thereby eliminating any possibility of incorrect manoeuvres and speeding up connection/disconnection operations.

MANUAL LEVELLING

Manual levelling is the distinguishing feature of our “F” series. By means of careful adjustment movements of the joystick, the operator brings the load back to a position parallel to the ground during material loading and unloading operations.

MECHANICAL SELF-LEVELLING SYSTEM

The mechanical self-levelling system is provided as standard on “M” loader models. Thanks to this device, the load is kept in the same position for the entire lifting phase, giving the loader a greater lifting force. The variable geometry parallelogram allows very large working angles, improving performance and increasing ease of use.

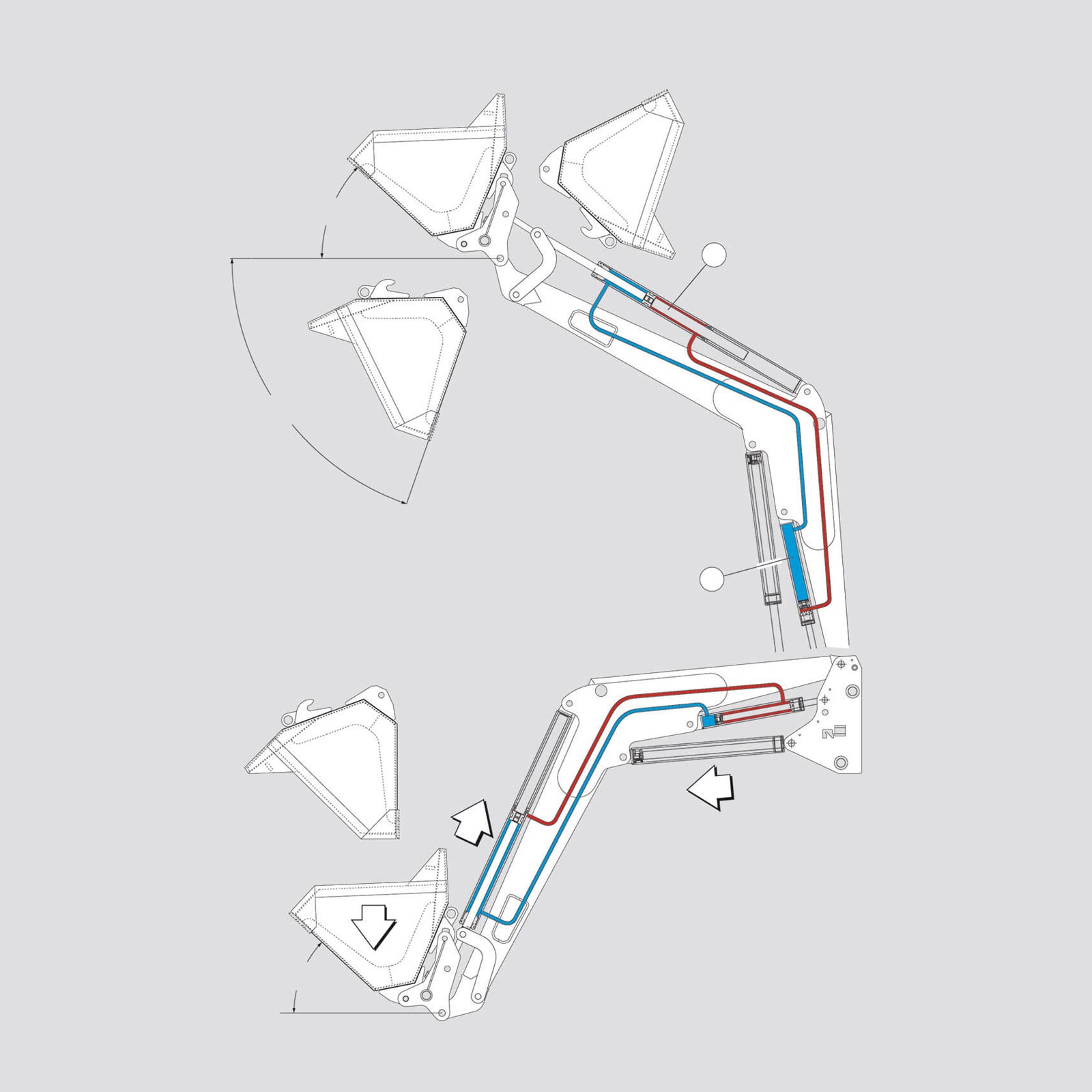

HYDRAULIC SELF-LEVELLING SYSTEM

Self-levelling of the implement is achieved by means of suitably sized compensating jacks A connected in a closed circuit to bucket jacks B. When the boom is raised, a quantity of oil is ejected from the compensating jacks which, when fed into the bucket jacks, automatically levels the implement. The same happens, conversely, when the boom is lowered.

The compensating jacks also lead to an increase in lifting force: the “Q” load on the implement generates pressure in the bucket jacks and consequently also in the compensating jacks. The resulting increase in force can be quantified as 10÷12% of the load Q.

The hydraulic self-levelling system is provided as standard on “H” loader models.

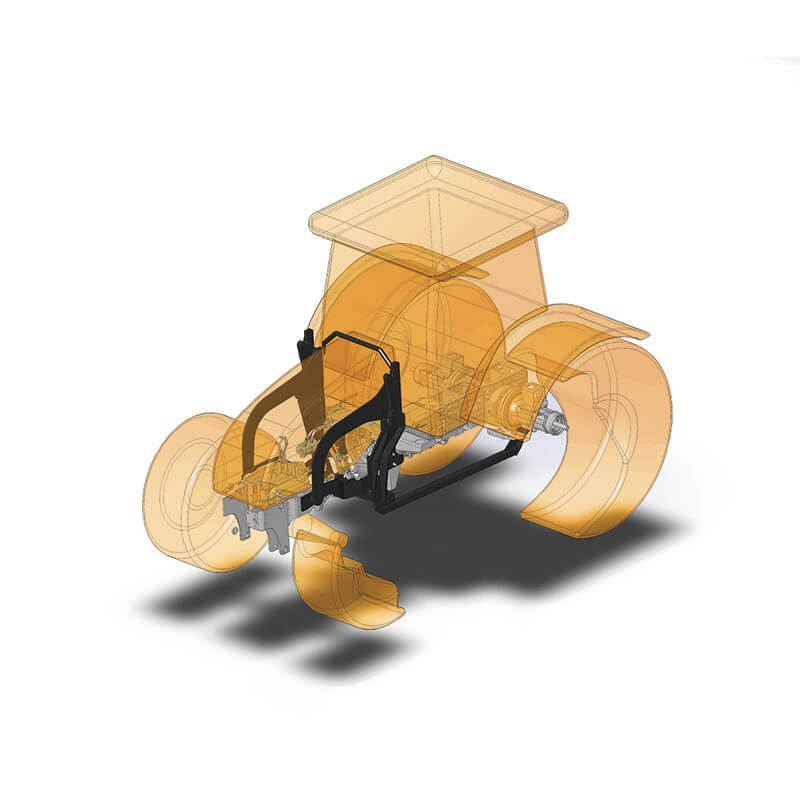

COMPACT tool carrier

Designed for easy and fast replacement of implements. To be used only with implements specific for PC models.

COMPACT -> EURO 8 adapter

Accessory that allows the use of implements equipped with Euro 8 attachment compatible with the PC series.

Available in two versions: the first version for PC1, PC3 and PC4 series, the second version for PC2 series.

ECO EURO tool carrier

Designed for easy and fast replacement of implements on CHROME front loaders. The loader is supplied as standard with Euro 8 system compliant with ISO 23206 standard. This allows hitching all the implements compliant with these standards.

Sigma 4 tool carrier

Designed for easy and fast replacement of implements with Sigma 4 attachment.

EURO 8 tool carrier

Designed to allow the use of implements compliant with Euro 8 standards and, with the addition of the dedicated MX adapter kit, MX implements can be hitched. In addition, it is possible to transform the Euro 8 attachment to Euro 8 HYDRO by adding a hydraulic linkage thanks to the dedicated optional kit.

EURO 8 HYDRO tool carrier

The Euro 8 tool carrier with hydraulic function is suitable for contexts requiring frequent hitching and unhitching operations. This type of tool carrier, to be used with the Sigma 4 joystick, allows the locking pins of the implement to be opened and closed directly from the tractor driver’s seat, to ensure maximum comfort.

Hitching and unhitching of the implement are carried out by simultaneously pressing 2 buttons on the loader joystick, thus avoiding unintentional manoeuvres and ensuring the maximum possible level of safety. The Euro 8 HYDRO attachment requires an additional dedicated hydraulic line for its operation.

It is possible to transform a mechanical Euro 8 attachment into the Euro 8 HYDRO version using the dedicated optional kit.

EURO 8 HYDRO M tool carrier

Euro 8 tool carrier manufactured with double-acting single piston hydraulic linkage, to be used with the Sigma 4 joystick. The hydraulic function allows to open and close the locking pins of the implement directly from the tractor driver’s seat, ensuring maximum safety by pressing the 2 joystick buttons. The tool carrier requires an additional dedicated hydraulic line.

MULTI tool carrier

Designed to allow the simultaneous use of Euro 8 compliant implements or implements with Quicke/Trima attachments. Optional adapters can be added to attach implements with the MX attachment.

SKID STEER tool carrier

Designed to allow use of implements with a SKID STEER type attachment.

Euro 8 tool carrier for rear 3-point hitch attachment

This tool carrier is used for quick hitching and unhitching of implements with Euro 8 3-point hitch positioned at the rear of the tractor.

Euro 8 tool carrier for FGB COMBI on mobile frame

Designed to equip implements with the Euro 8 attachment easily and quickly.

This tool carrier can be fitted to the mobile frame of the FGB COMBI.

Euro 8 tool carrier for FGB COMBI fixed on arch

Designed to equip implements with the Euro 8 attachment easily and quickly.

This tool carrier is directly fitted to the arch of the FGB COMBI.

High-tipping function

for buckets without additional hydraulic lines

The high-tipping function can be applied to all types of buckets that do not have additional hydraulic functions and allows our implements to overcome the limits of standard unloading activities, allowing to unload more easily under variable loading bed height conditions. It requires a third hydraulic line.

NEBULA SYSTEM

Anti-shock safety shock absorber.

The NEBULA SYSTEM is designed to greatly reduce the physical stress on the operator, thanks to the use of two nitrogen accumulators, which cushion the stress on the loader and tractor caused by heavy impacts during loading and transport. The perceived benefit grows, becoming more noticeable as speed and load increase. The system also contributes to a significant reduction in tyre wear as well as wear on the tractor's front transmission. The NEBULA SYSTEM comes as standard with a transverse cover that makes it invisible and protects it from shocks and external wear and tear, and with a bypass tap to deactivate it under specific circumstances.

NEBULA SYSTEM video.

Water testing

The innovative NEBULA technology allows our loaders to maintain a much more stable load. Thanks to the water test, you can see with your own eyes that when a bucket is filled to the brim, even with a liquid material, the NEBULA's cushioning function minimises jolting and spillage of contents.

EASY MAINTENANCE

We design our subframes in such a way as to facilitate access to tractor parts that need regular maintenance as much as possible.

HYDRAULIC PIPE SUPPORT BRACKET

Offered as standard on all loaders, the dual-position bracket allows the loader pipes to be comfortably supported, either with quick-release connections or with the FLASH SYSTEM multiple connector, when the loader is uncoupled from the tractor.

BUCKET LEVEL INDICATOR

A standard feature on all models, the bucket level indicator makes it easy to see from the driver's seat the exact angle of the implement in relation to the ground, making it significantly easier for the operator to manoeuvre.

SUPPORT FEET

As the only ones on the market with this type of arrangement, our support feet are longer, as they are designed to adapt to all types of terrain, thanks to a simple tie rod adjustment system. During operation, the feet are housed inside the boom so as not to interfere in any way with the front tractor wheels.

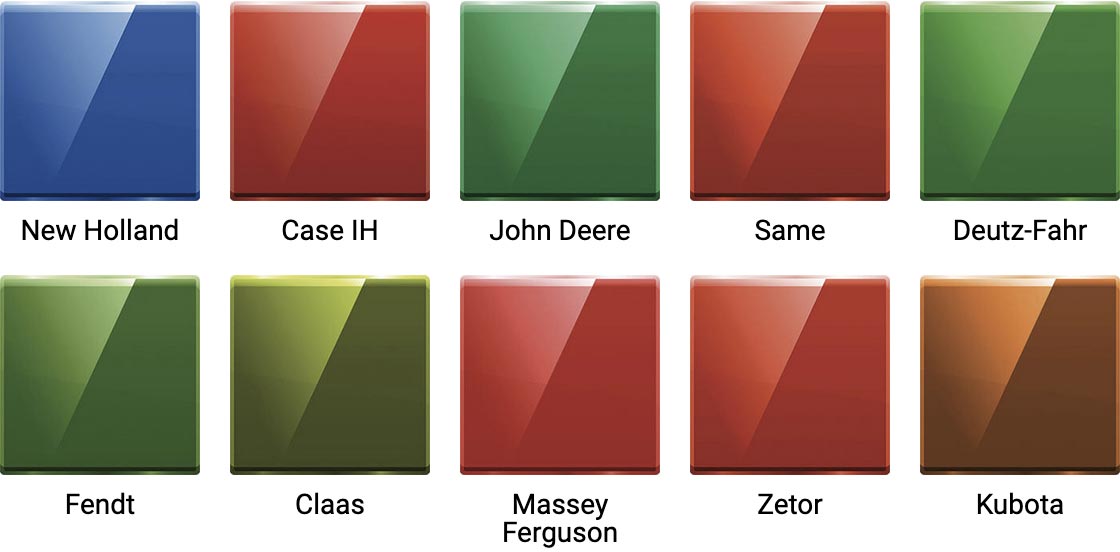

COLOUR

In addition to the standard embossed grey RAL7021, the Sigma 4 front loaders are also available in different colours on request.

Sigma 4 front loaders are painted via an industrial process with the following steps: washing/degreasing, sandblasting, primer application, enamel application, firing.

This process guarantees a salt spray resistance of over 700 hours.

These characteristics allow the product to maintain the colour tone and paint adhesion, which sets our product apart from the competitors.