Loader with implement hydraulic self-levelling system

Standard equipment

Available for the 10, 15, 20, 30 and 40 series.

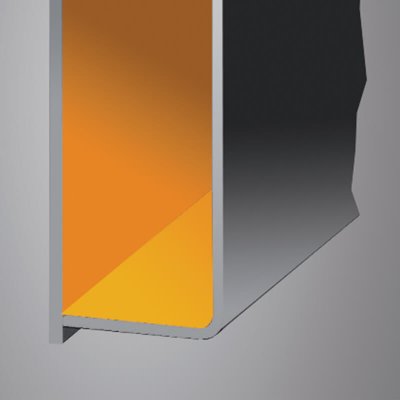

The boom section is composed externally by a single metal sheet and internally by two “C” section bars. This industrially adopted solution provides the boom with high strength combined with remarkable lightness.

The TC Basic joystick is supplied as standard with all mechanical distributors and controls the hydraulic lines for loader lifting and implement movement. Its shape has been carefully developed by Sigma 4 to offer maximum comfort under all conditions of use, no matter where in the driving area it is installed.

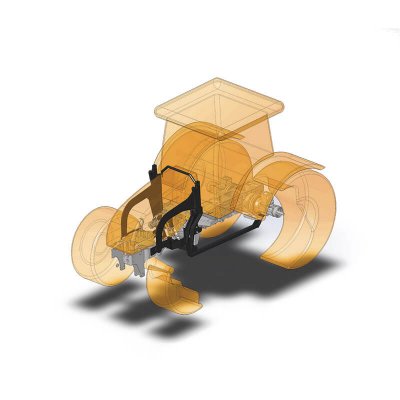

The support feet, equipped with fine adjustment system for the CHROME, IRON and TITANIUM models, can be singularly adapted to ensure maximum safety and adaptability during parking manoeuvres on all types of grounds, even the most uneven. During normal operations, the feet are locked inside the loader boom, so that they do not interfere with the front tractor wheels.

The VELOTAK quick-release system, patented by Sigma 4, makes it possible to speed up and simplify the hitching/unhitching of the device, by performing the operation in a single lowering phase from the tractor. In fact there is no need to insert pins or use special tools, just operate the lever located on the outer side of the bearing boxes to hitch and unhitch the device in just a few seconds. The hitching and unhitching positions are indicated by a dedicated coloured decal. The device is designed with a passive safety device so that it will always be hitched even in the event of an unforeseen incident or breakage. The support feet are millimetrically adjustable to allow operation on any terrain and slope. The VELOTAK system is standardised for use on all SIGMA 4 loader models.

Designed to allow easy and fast hitching and unhitching of implements with Sigma 4 attachment.

The adoption of flexible pipes has allowed the hydraulics to be largely located inside the boom, providing improved visibility and protecting it from shocks, wear and dirt deposits. An anti-bursting protective sleeve is also supplied as standard for increased operator safety.

The bucket level indicator allows the operator to easily verify, from the tractor driver’s seat, the angle of the implement with respect to the ground.

The Euro 8 tool carrier with hydraulic function is suitable for contexts requiring frequent hitching and unhitching operations. This type of unhitching allows the locking pins of the implement to be opened and closed directly from the tractor driver’s seat, to ensure maximum comfort. Hitching and unhitching of the implement are carried out by simultaneously pressing 2 buttons on the loader joystick, thus avoiding unintentional manoeuvres and ensuring the maximum possible level of safety. The Euro 8 HYDRO attachment requires an additional dedicated hydraulic line for its operation. It is possible to transform a mechanical Euro 8 attachment into the Euro 8 HYDRO version using the dedicated optional kit.

Euro 8 attachment manufactured with double-acting single piston hydraulic linkage. The hydraulic function allows to open and close the locking pins of the implement directly from the tractor driver’s seat, ensuring maximum safety by pressing the 2 joystick buttons. The tool carrier requires an additional dedicated hydraulic line.

Designed to allow the simultaneous use of Euro 8 compliant implements or implements with Quicke/Trima attachments. Optional adapters can be added to attach implements with the MX attachment.

Designed to allow use of implements with a SKID STEER type attachment.

_jpg_400_400_cover_85.jpg)

The TC Profi joystick is equipped with two buttons on the back of the joystick and is supplied together with systems with mechanical distributors equipped with third or third and fourth hydraulic line.

_2_jpg_400_400_cover_85.jpg)

The TC Profi Advanced joystick, with 8 buttons, is supplied as standard in the event that a fifth hydraulic line is installed in a system with a mechanical distributor, which is used for the hydraulic quick-release function of the implement.

it is possible to use this joystick for several additional functions:

- operate a 3rd hydraulic line

- operate a 4th hydraulic line

- change gears

- engage and disengage the shock absorber directly from the cab

- switch lights on and off.

The TC Speed is an electronically-controlled joystick, supplied as standard with the electronic and mechatronic distributors. The use of the Can Bus, a data transmission cable, makes installation significantly easier compared to mechanical configurations, adapting even to the smallest joystick supports. Movement management via electronic software allows the front loader to be moved with greater precision.

The TC Speed allows the following functions to be controlled:

- operate the 3rd hydraulic line

- operate the 4th hydraulic line

- operate the 5th hydraulic line

- engage and disengage the shock absorber directly from the cab

- engage and disengage the floating function

- switch the joystick system on and off.

| H10 | H15 | H20 | H30 | H40 | |||

|---|---|---|---|---|---|---|---|

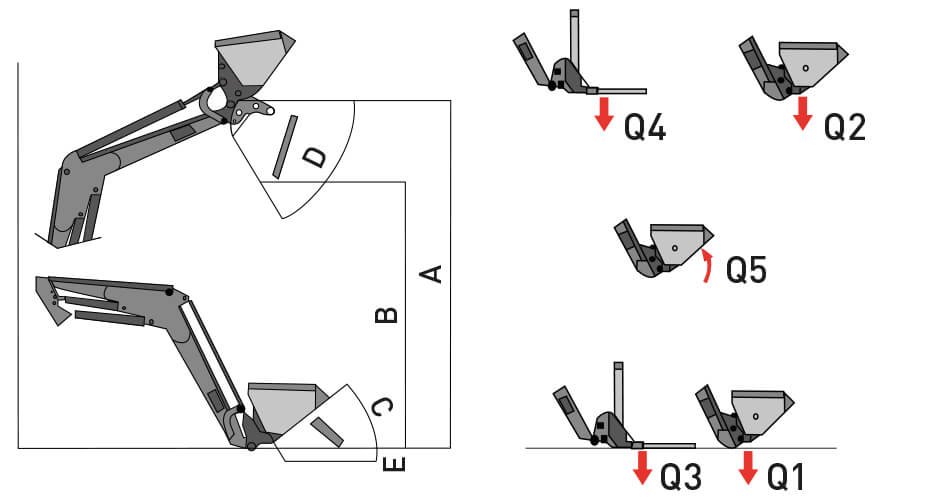

| With bucket on the ground 300 mm from the pivot point | Q1 | 1100 | 1100 | 1500 | 1700 | 1900 | |

| With bucket at maximum height 300 mm from the pivot point | Q2 | 1000 | 1000 | 1400 | 1600 | 1800 | |

| With fork on the ground 600 mm from the pivot point | Q3 | 1100 | 1100 | 1500 | 1700 | 1900 | |

| With fork at maximum height 600 mm from the pivot point | Q4 | 1000 | 1000 | 1400 | 1600 | 1800 | |

| Breakout force at the tine | Q5 | 1500 | 1500 | 1500 | 1500 | 1500 |

| At pivot point | A | 3200 | 3300 | 3800 | 3870 | 4100 | |

| Under bucket level | B | 2260 | 2360 | 2940 | 3010 | 3200 |

| Maximum rollback angle at ground (bucket) | C | Degrees | 45 | 45 | 45 | 45 | 45 |

| Maximum dump angle (bucket) | D | Degrees | 55 | 55 | 55 | 55 | 55 |

| Digging depth | E | 150 | 150 | 150 | 150 | 150 |

| Lifting time to maximum height | Seconds | 7 | 7 | 7 | 7 | 9 | |

| Bucket dumping time | Seconds | 3 | 3 | 3 | 3 | 3 |

| Without implement and without tractor subframes | 443 | 443 | 500 | 533 | 560 |

| Of tractor | 45-85 | 45-85 | 60-100 | 70-120 | 100-150 | ||

| Of tractor | 30-60 | 30-60 | 45-75 | 50-90 | 75-110 |